Artificial intelligence expands machine tool capabilities

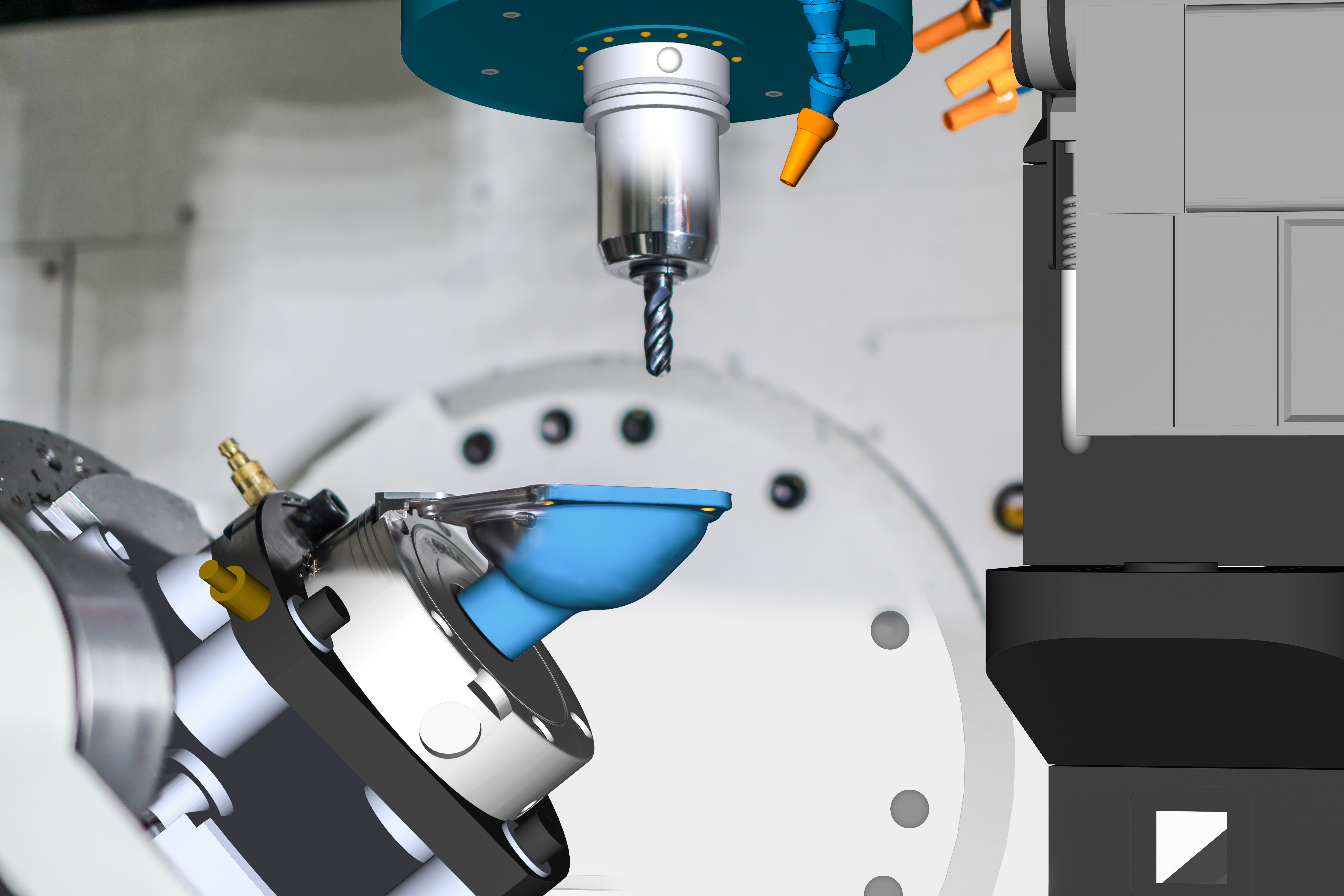

The fourth Industrial Revolution promises new efficiencies and productivity gains for manufacturers. Machine tool suppliers are integrating Industry 4.0 capabilities and software companies that are providing powerful new tools such as those that utilize artificial intelligence.

The fourth Industrial Revolution promises new efficiencies and productivity gains for manufacturers. Machine tool suppliers are integrating Industry 4.0 capabilities and software companies that are providing powerful new tools such as those that utilize artificial intelligence.

Machine tool manufacturers are creating solutions for job shops. Some recent AI innovations and benefits that machine tool manufacturers have introduced include:

- Predictive maintenance: Some tools come equipped with special monitors that track machine components such as a spindle on a mill.

- Collision avoidance: Systems run applications that simulate the cutting action a few seconds ahead of the live cut, predicting collisions and shutting down the process to prevent damage.

- Reduced overhead: Machine tools require a massive amount of energy, even when they’re idle. Many machine tools use AI in the form of meters and sensors to evaluate a machine’s energy usage and make decisions on how to reduce energy.

Machine tools capabilities are augmented by powerful software that can adapt to changing needs and customer specifications such as the ESPIRIT CAM software from DP Technology. The software has the ability to be updated as frequently as new innovations become available.

features include:

Machine swap

There are many different scenarios that might require a new program for a different machine: an inoperable machine, the need to increase production, or a move from prototype to production. This ESPIRIT feature uses an AI to automatically update a program any time a setup change is made or machine swapped. It can also automatically detect setup changes without manual input.

Exclusive Article : Tips for Using Industrial Robotics in a CNC Machine Shop in 2021

Automatic links

Users can create a cutting cycle and then AI-driven software can create the fastest and safest positioning between tool operations with consideration of the limits of specific machines. With automatic links, users can set a machine’s prioritization.

Simulation, analysis, and verification

These capabilities take the collision avoidance feature to a new level, including generating a digital twin of the entire machining environment to review a machine’s kinematics, reviewing the potential for collisions, axes overtravel, acceleration exceptions, and other conflicts before making a single cut.

Machine awareness

This feature allows users to define a process plan for a single workpiece independent of the machine and workpiece set up. For example, select the tooling and the cutting strategy, and AI automatically adapts, sequences, and optimizes the list of tasks to be performed.

Stock-aware toolpath

AI-driven software analyzes the real-time state of a company’s stock, eliminating air cuts and minimizing repositioning, which often leads to improved efficiency and, often, significantly reduced cycle times.

Synchronization

Multichannel machines are especially useful because they can concurrently perform different actions. An AI engine automatically synchronizes and sequences the program for optimal use of the machine, and to avoid collisions.

Short-run and production programs

Many times, switching between short runs for small lot sizes and multi-part production runs for larger lots seems like more trouble than it’s worth. With AI machine awareness, job programs can be reorganized, maximizing process concurrency across multiple parts and optimizing cycle times.

Intelligent work coordinates

For tombstone, fixture, and work offset management, an AI engine can offer an automatic selection of work offset and coordinate transformations based on its awareness of the job. The system determines local references for every local machining feature and activates the necessary machine functions including RTCP, tilted plane, and dynamic fixture offset.

Capturing best practices

Features such as US SHOP TOOLS KnowledgeBase eliminate the need for manual recall of a shop’s best machining practices. Instead, it stores them in the software, allowing an operator to access needed information.

With the right tools, automation in a shop can deliver what Industry 4.0 has long promised—highly efficient manufacturing that doesn’t sacrifice safety for speed.

Source: espritcam

Comments

Post a Comment