5 Ways Machine Tools Are Impacted by Industry 4.0

Industry 4.0 is coming. It’s something everyone knows, without a doubt, because the point has been beaten to death. Industry 4.0 is a buzz phrase to describes the future of manufacturing.

The Industrial Revolution

(3.0) introduced greater productivity, achieved with the help of

technology; 4.0 is about using tech and efficient processes alongside more

intelligent platforms. Things like IoT,

AI, machine learning and big data are all being used to augment and enhance

the manufacturing field.

What does this mean for specific areas of manufacturing, in

particular for machining? How is Industry 4.0 going to impact machine

tools and related manufacturing technology?

The answers reveal that, like all of manufacturing, machining operations are heading toward a more streamlined,

connected and intelligent network of machines, devices and systems. Connected

processes either will replace conventional machines completely, or the

connected devices will be synched with legacy systems to ensure the

accessibility massive streams of data.

Then, the digital content will be ingested, processed, and

analyzed to improve existing operations, or to initiate entirely new ones. It

also will allow human laborers to take a more hands-off approach, getting

involved only when necessary.

Machine

tools are a significant feature of this new environment. Industry 4.0

will change how they are applied in the average shop or facility.

1. Preventive maintenance = persistent operation — Conventional

manufacturing technologies and machine

shop tools aren’t always reliable. Downtime increases costs, including

production, labor, and maintenance fees. For a business that produces about 600

units per hour at an average profit of $50, just one hour of downtime means a

huge loss of $10,000 in revenue.

Naturally, it’s important to eliminate downtime and deal with problems as soon

as possible.

On demand

article : Top

5 robot trends in 2021

Industry

4.0 introduces an entirely new opportunity in the form of

preventive maintenance. With a robust stream of performance and real-time data,

maintenance crews can prepare better for equipment malfunctions or errors.

Budding issues can be detected early and dealt with before regular operations

grind to a halt.

Big Data solutions even make it possible to build predictive

models and algorithms that can be used to identify potential failure points,

many of which otherwise would have been invisible to the naked eye.

All this leads to machines and equipment that run continuously,

without failure, and at more efficient levels than ever before.

2. Energy

and operational savings — It’s no secret that machine

tools and hardware use up a lot of power. They are energy hogs, even when

they’re powered down and just in standby. Resource usage can be managed better

with the help of Industry 4.0 solutions.

Incoming data — collected by IoT sensors and platforms — can be used to inform operations

better. Smart meters can be put in place to manage the flow of energy

efficiently. Equipment can be automated or powered appropriately to lessen

their environmental and resource impact.

Consider something as simple as smart lighting: When workers are

involved on a machine or factory floor, the lights obviously must be on.

Yet when the room is empty after a shift, those lights are most

likely still on. The entire system can be automated, using motion alerts and a

human presence to detect when they should be on or off. Turning off a shop’s

lights can save hundreds — if not thousands — of dollars per year. Imagine if

that very system were applied to other equipment and machines in a plant or

machine shop?

3.

Enhanced or automatic virtual metrology — Quality

assurance is a huge deal in the manufacturing field and has a lot more to do

with the machines and equipment in use than one might think. When a device

experiences a malfunction, loses its efficiency or is just plain inaccurate,

the developed goods suffer as a result.

That’s why manufacturers always have a quality assurance process

in place to inspect the goods or components for defects or minor errors. The

problem with many of these processes, however, is that they can cause delays in

production. They’re not always carried out regularly, which leads to many

products being pushed through in less than ideal conditions.

Industry

4.0 and the related technologies will transform this process

completely by introducing real-time QA through something like an automated virtual metrology (AVM) system.

Essentially, data is collected about the conditions, quality, and state of

goods, and this is combined with information about the machines and processes.

It gives a more complete profile of operations and introduces a real-time

element to QA inspections.

Imagine manufacturing operations continuing forward even during

a major QA inspection, with little to no interruptions and near-instant

feedback?

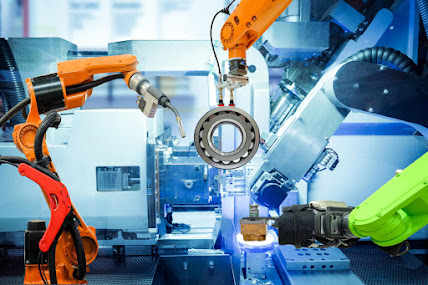

4. Better

human-machine interfaces — Improving the current

iteration of machine and manufacturing equipment isn’t just about performance

and regular operation. Also instrumental are the communication standards

applied for human-machine interfaces. Most workers will be conducting

day-to-day operations alongside robots and machines, commonly referred to as cobots.

The future machine shop or factory floor will be extremely

efficient as humans, machines and robots work side-by-side in a smooth, safe

environment. To get there, however, human-enabled interfaces need to be vastly

improved. Technicians will be able to remotely operate equipment and deliver

commands on the fly. Reporting systems will provide real-time alerts and insights

to operators, no matter where they are.

5. New

machining centers — Before Industry 4.0 can really take off,

the manufacturing infrastructure needs to be put in place. Every connected

device in the machine shop requires a reliable, active connection to the

network, whether that is private or public.

Manufacturing facilities and machine shops will need to be rezoned to

implement these new connectivity solutions. How do you move equipment and

retool spaces, for instance, to maximize signal strength? Will signal boosters

and stronger network tools need to be put in place to reach certain areas of a facility? What equipment must be

upgraded entirely, and what can be improved by syncing up IoT and third-party

sensors?

While it’s happening, it makes sense to consider the efficiency

and productivity of the location, in general. What other improvements can be

made to lessen energy use or resource usage? Are there more efficient ways to distribute equipment? Can

productivity be improved by shifting designs or layouts?

Industry

4.0 and its adoption will largely affect how machines are

distributed within a shop or facility. Smarter, more aware environments are not

a pipe-dream but something that is possible and more important than ever.

Sensors will be used to monitor this information and find better, intelligent

ways to structure a plant or shop.

Exclusive : Machine

shop tools Blog 2021

Optimal

productivity is the way to go — Many of these solutions

service have one particular benefit in general, and that’s enhanced

productivity. The primary method for achieving this is to augment existing

machine tools and hardware to be conducive to an intelligent environment.

Where machines aren’t upgraded entirely, it’s possible to

implement IoT sensors and similar devices to gather the necessary data and

streamline metrics. It’s not just about being more informed — it’s just as

important to introduce smarter controls. Smart, connected equipment services this

idea by offering remote functionality and networking support.

Comments

Post a Comment